Difference between lever and pump driven espresso machines

Difference between a lever and a pump driven espresso machine

Let´s start with the principles of a lever brew group and a pump-driven brew group.

The invention of the lever espresso machine took place in 1948 after the Second World War in Milan by Achille Gaggia. This created a completely new way of making coffee. From this point on , the principle of lever espresso machines remained broadly the same.

- The body of the lever brew group was made from casted brass, to increase temperature stability.

- The piston – it presses the water through the coffee puck. With a lot of brew groups like the ones ofFaema,Rancilio, Astoria the piston also contains the piston seals. These seals make sure that water isn’t forced out the top of the brew group during the brewing process.

With some espresso machines, like the early Gaggia and Victoria Arduino espresso machines, the piston is a smooth cylinder and the gaskets are located inside the body of the brew group. At the moment, however, there isn’t any manufacturer which still produces the wall gasket type of brew groups.

- The spring – or in some cases springs. When you pull the lever down, the piston and shaft are raised, which makes the spring (s) to compress. A famous exception to this system is the La Pavoni Europiccola, this machine doesn’t have a spring but uses the force of the user.

When the piston is in the up position the water will flow out of the boiler (which happens due to boiler pressure) into the brew group. When you raise the lever, the piston will close off the boiler and force the water through the coffee. How fast the lever will go up depends on the fineness of the coffee and the amount of force used to compact it.

- Flow regulation. Most lever groups do have a valve on the “neck” of the group to regulate the amount of water coming out of the boiler when the piston is raised. This can be easily adjusted on most machines by screwing in an axle to reduce the flow from the boiler.

- Dipper tube system. The water of the brew group comes directly out of the boiler, instead of feeding it through an HX system.

- Pressure. The spring doesn’t give a constant pressure throughout the brewing process since it loses its force while traveling to its original position. It is said that the average pressure of the spring is 9 bar.

The invention of the pump-driven machine took place almost 15 years later with the famous Faema E61, which is still a classic machine to this day. The style of the E61 brew group style is still the most popular brew group of modern household and commercial espresso machines. In this text, we talk about the basic pump driven espresso machines, not the high-end machines.

There are two different types of pump-driven machines, manually and electronically controlled machines.

The manually controlled machines work with the lever principle of the E61 brew groups.

When the lever is in the lowered position, a cam opens the upper valve part and a microswitch is turned on to operate the internal or external motor. The water then exits the brew group at a pre-set pump pressure.

When the cam is in the raised position, the upper valve closes and the lower drain valve opens. At the same moment, the pump stops as soon as the microswitch is switched off again.

The electronically controlled brew groups (on/off without timer) work slightly different but the principle is the same. When you push the button to start the brewing process the following things will happen:

- The 3-way solenoid valve opens and the pump starts. If you want to stop the brewing process, you must press the button again. The pump then stops running, the solenoid valve closes again and the wastewater leaves the brew group in the direction of the 3-way solenoid valve.

- Pressure: In a pump-driven espresso machine, the pressure is adjustable and remains stable throughout the brewing process.

- Brew group inlet: Most pump espresso machines use a heat exchanger system (HX). In this system, no water is taken from the boiler. The water instead passes through pipes or coils that go through the boiler and thereby heats to brewing temperature. On the more expensive machines, you will find double or multi-boiler systems. These have the option to set the temperature per group.

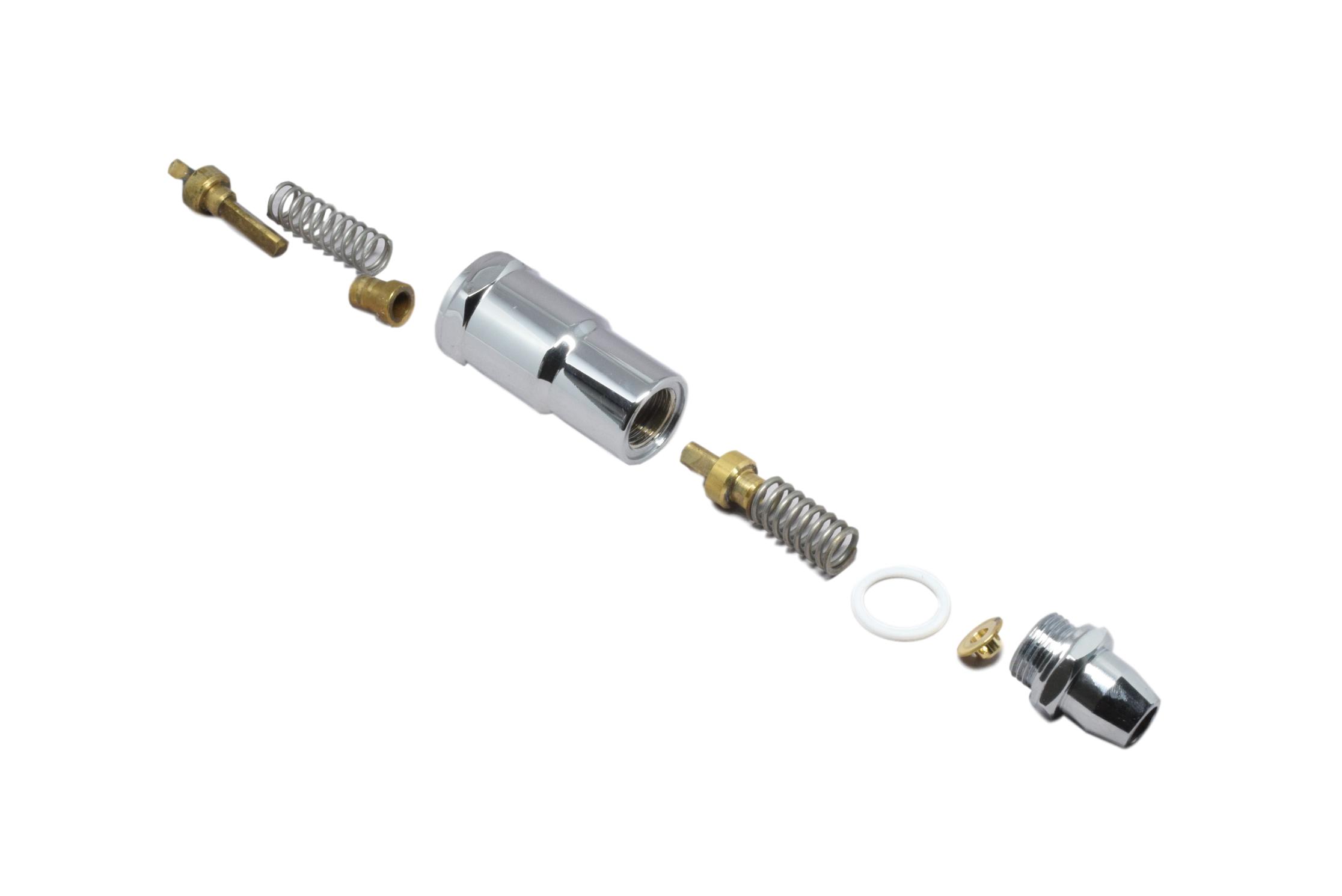

- Flow regulation: For most pump-driven espresso machines, the flow regulation is fixed with a gigleur inside the brew group. This is a small nut with a hole inside. This hole, whose diameter varies from 0.5 mm to 1 mm, limits the flow.

So, is there a difference between a lever machine and a pump machine? Yes, there is.

One of the most important things is practicing. Making espresso with a lever espresso machine takes a lot more trial and error. What is the correct setting of the regulator screw? How long to pre-infuse the coffee (hold the lever in the lowered position, so the water can flow out of the boiler)?

On the other hand, is making a good espresso with a pump-driven espresso machine easy if you don’t have any experience? Sorry, no. Pump-driven machines also require a lot of practice. Some machines allow you to pre-infuse, but not all. Compared to a lever machine, you can easily adjust the brewing pressure. It is more difficult to adjust the pre-infusion because the flow regulator is fixed on most machines.

Whether a lever espresso machine is better than a pump machine depends on the attitude of the person using it. It depends on the user. The four key elements for a good espresso are the coffee quality, the water quality, the consistency of the grinder and the experience of the person making the espresso. In conclusion, we can say that if you have the most expensive espresso machine that you can buy, the end product will be unsatisfactory if you use poor-quality coffee or the other key elements are not performing in the best way.