Espresso machine pressure switch

Pressure switch

The first pressure switches used on vintage espresso machines were actually mercury filled switches. A membrane expands under the pressure of the boiler which tilts the mercury filled tubes. The mercury flows to the opposite side and the power is turned off. Because mercury is a metal, it conducts electricity. When the boiler pressure drops, the membrane lowers and the mercury filled tubes are levelled out and create a circuit again.

These switches are no longer allowed in the Netherlands for espresso machines1. This may vary for other countries, where it is can still be allowed to use the mercury filled espresso machine pressure switches.

After the mercury switches came the modern pressure switches. There are 2 types of pressure switches, both are spring adjustable. There are the higher amp pressure switches for commercial machines of Sirai and Parker on the one hand and the lower amp pressure switches of Ceme and Ma-ter on the other hand.

The high amp switches are available as 1- and 3- phase pressure switches. These switches can be partially serviced by replacing the membranes and the gasket.

Sirai and Parker type espresso machine pressure switches consist of the following elements:

- Brass connector and membrane holder

- Ring, membrane unit and rubber closing ring

- Pressure adjustment spring and screw

- Body

- Contactors

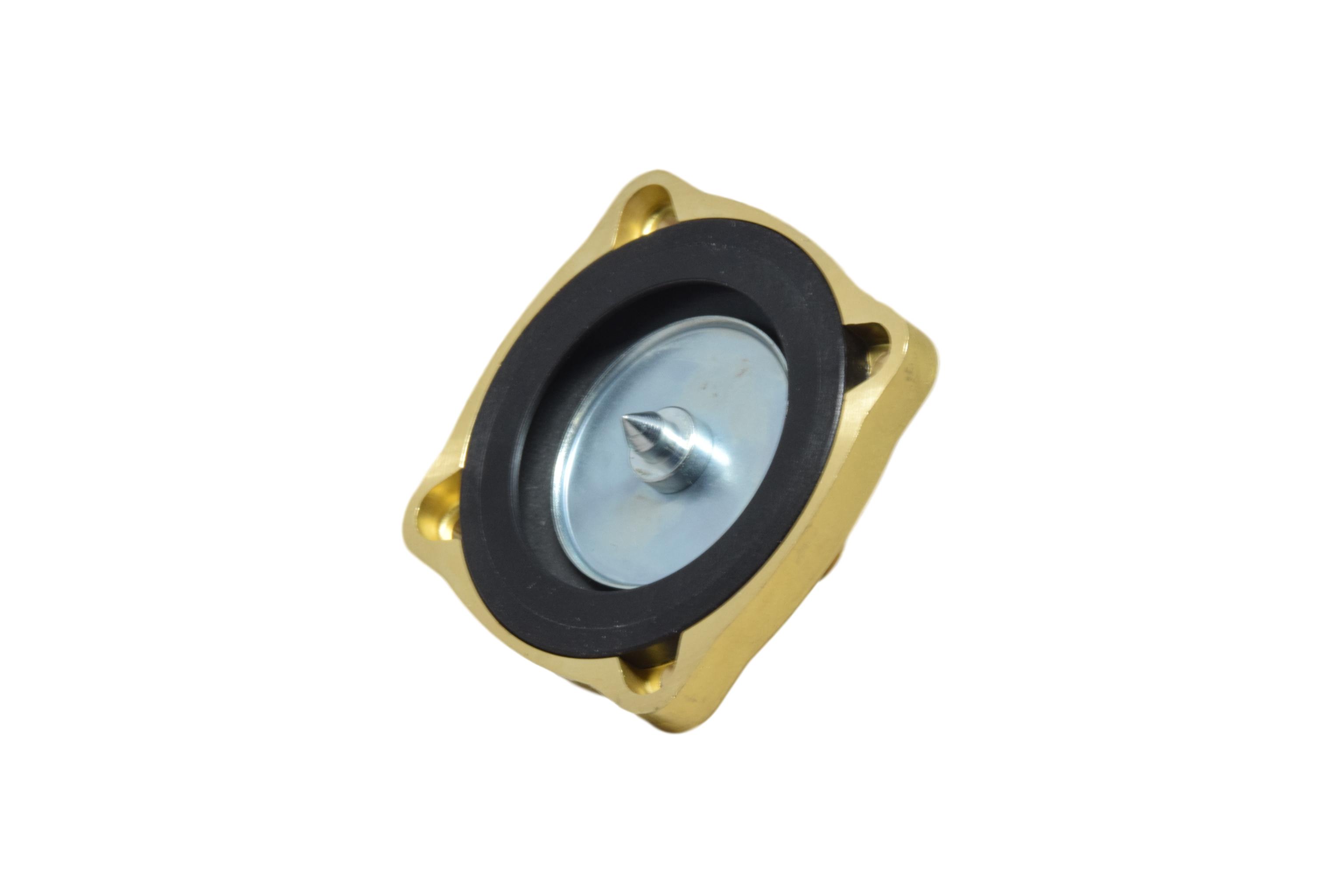

Brass connector and membrane holder

This part connects to a tube that carries the pressurized air from the boiler to the pressure switch. The connector is normally a 1/4” or a 1/8” bsp-g thread, depending on the type of pressure switch. The 1/4" bsp-g thread is more commonly used and is utilized on most commercial and domestic espresso- and coffee machines.

Membrane

The brass connector holder also holds the pressure switch membrane set. This membrane set consists of 3 components:

- The ptfe bottom membrane - the pressurized air pushes against this part of the membrane.

- The membrane unit - this is a flat rubber disk with a metal disk and a metal rod or pin in the middle.

- The rubber ring - this rubber ring keeps the ptfe bottom membrane and membrane unit in place.

Pressure adjustment spring

With the spring on the inside of the pressure switch, you can control the cut-off pressure of the pressure switch. For the Sirai pressure switches, this value can be between 0.3 bar and 1.7 bar; for the Parker pressure switches between 0.5 bar and 1.4 bar. These pressure settings vary for the different models. The switches of both manufacturers work however basically the same.

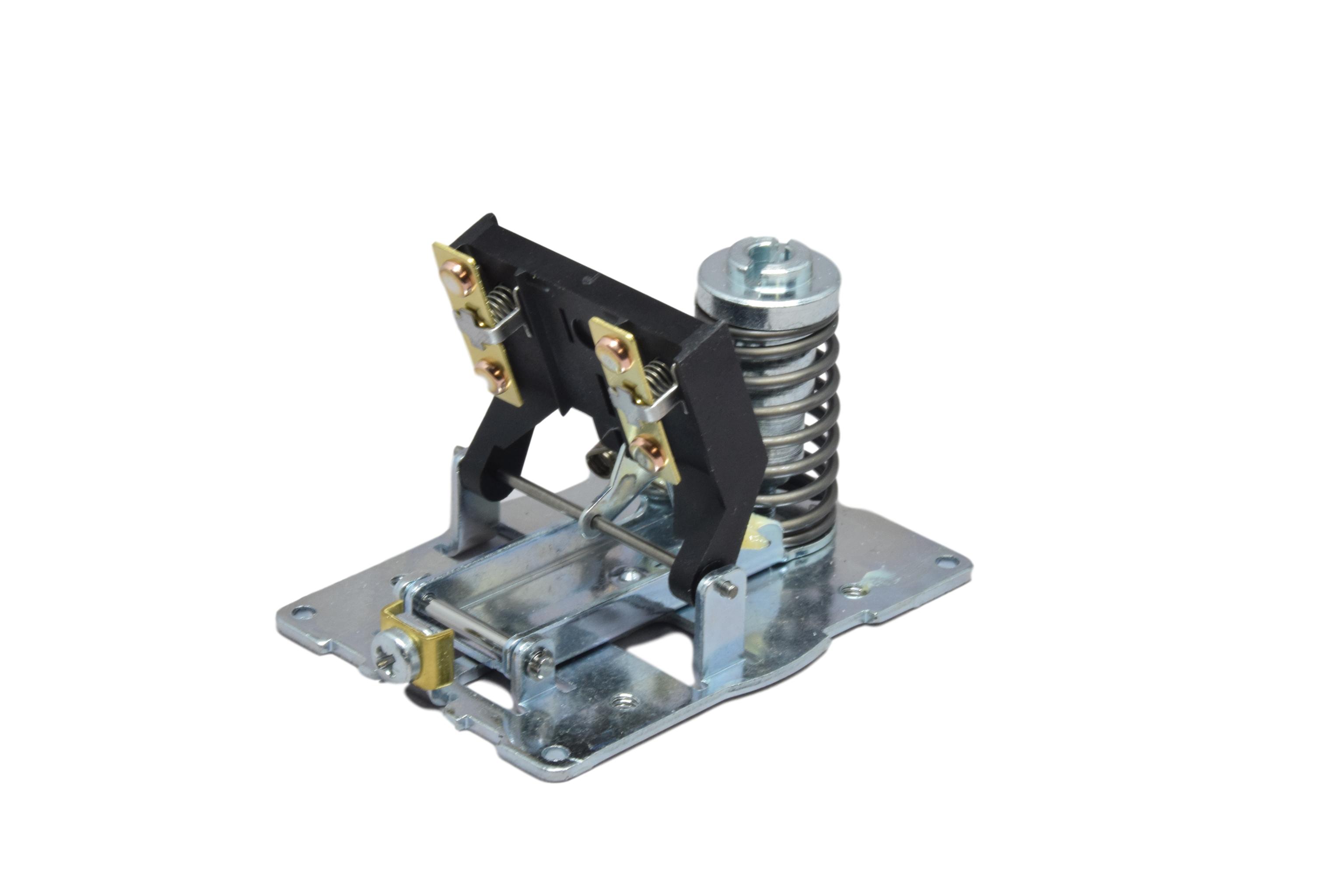

Body

The bodies of both types of pressure switches are partially made from a plated stamped base; the cover is made of glass fibre reinforced plastic.

Contactors

For the Sirai pressure switches there are 2 versions. The 20A switches have a base made of fiberglass-reinforced plastic lined with brass conductors. The 30A pressure switches have a metal body with ceramic insulators in which the brass conductors are located.

The Parker pressure switch works on the same principle as the 20A Sirai pressure switch.

But how does this type of pressure switch work?

The boiler pressure presses the membrane with the pin into the housing of the pressure switch. Within the housing, the pin presses on one side against a lever, on the other side of which is the adjustable spring. If the spring is compressed the pressure to turn off the machine needs to be higher and vice versa. In the middle of the lever is another pin that pushes, so when the lever raises to a certain point the contactors will move away and the power is cut off.

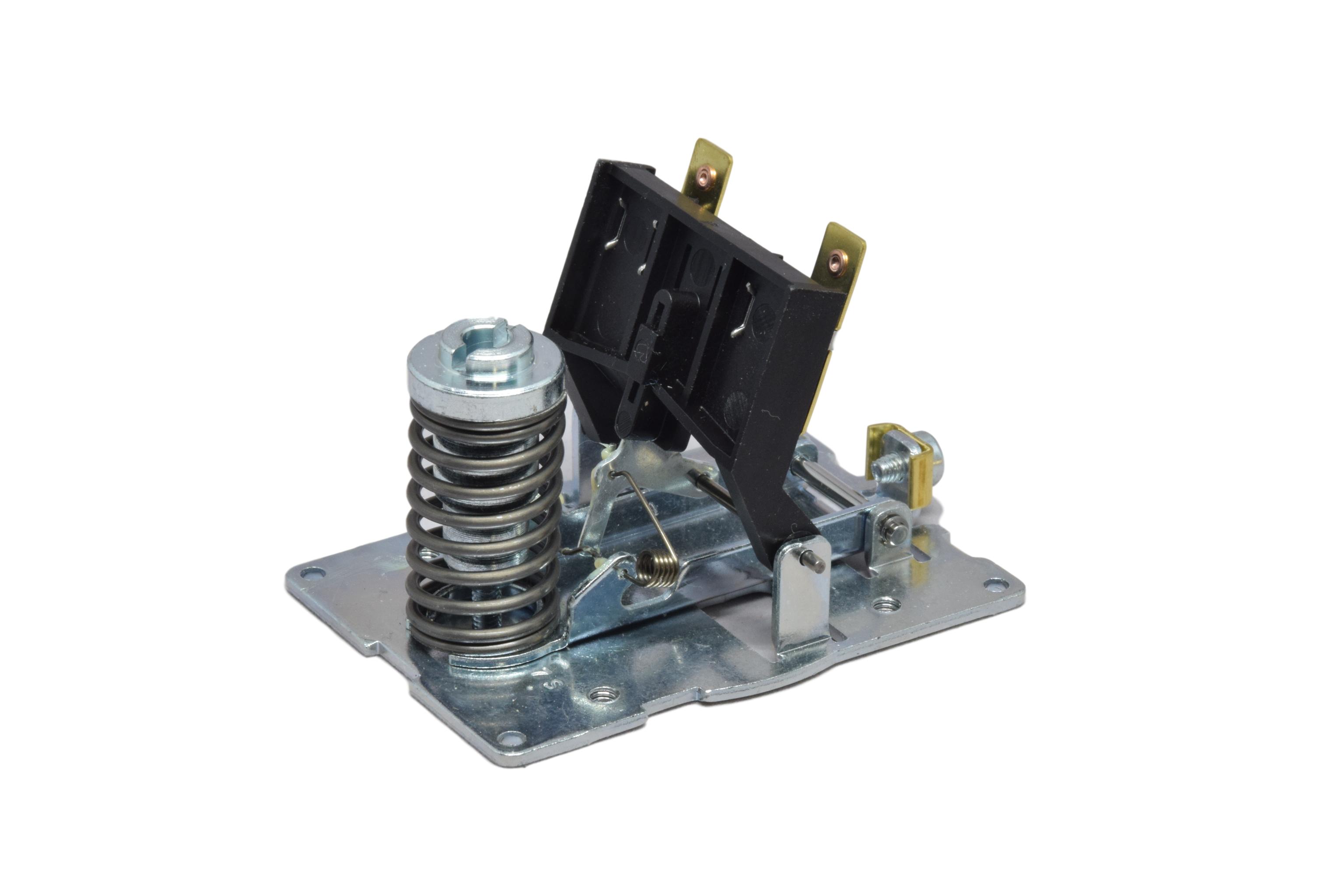

Microswitch operated pressure switch

Now we can discuss the pressure switches made by Ceme and Ma-ter. These switches are normally designed for up to 15A, this limitation is due to the microswitch. Their function is suitable for domestic appliances and small commercial espresso machines. This switch is a non-serviceable pressure switch since you cannot reach its internals, unless you cut it open.

The Ceme and Ma-ter switches have the following components:

- Brass connector and membrane holder

- Ring, membrane unit and rubber closing ring

- Pressure discs

- Spring

- Microswitch

Casted brass connector and holder for membranes

To the casted brass connector, a tube is attached, which supplies air from the boiler to the espresso machine pressure switch. This tube is connected with a 1/8” or a 1/4” bsp-g thread, depending on the type of pressure switch.

Ring, membrane unit and rubber closing ring

On the bottom there is a silicone ring to seal the pressure switch. Above it is a metal membrane. This membrane presses with the pressure discs against the top assembly; the bottom section is closed with a plastic ring.

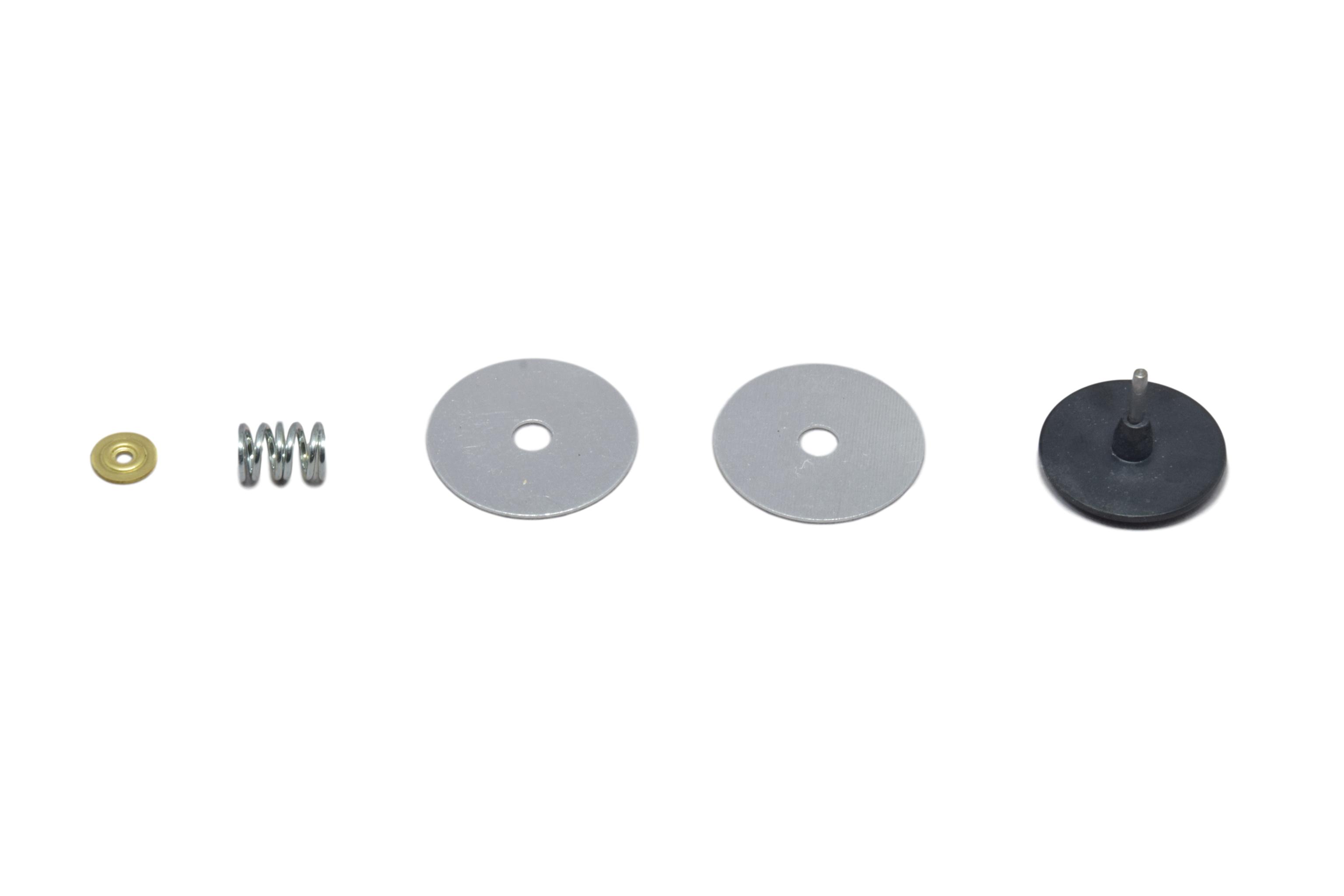

Spring assembly

The top section consists of the following components:

- A plastic guide with guide rod

- 2 galvanised discs

- The compression spring

- The brass washer

- The plastic housing with adjustment screw

This assembly is placed above the pressure membrane. When the pressure membrane moves up, the pressure guide is pushed upwards. The upper disc of the galvanised discs presses with the pre-set pressure against the microswitch and stops the current. This pressure can be adjusted by screwing in the adjusting screw. This compresses the compression spring and increases the resistance to the membrane, thereby shutting it off at a higher pressure.

If you want to replace your pressure switch, check the following points:

- The model – is it a single, 2- phase or 3- phase pressure switch?

- The connection – is it a 1/4” bsp-g thread or a 1/8” bsp-g thread?

- Wat is the maximum switching current, 16, 20 or even 30 amps?

- What is the rated switching voltage of the microswitch on the pressure switch, since some of the switches are only designed for 110V?