- Espresso Machine Parts

- Espresso machine brand

- Aurora-brugnetti

- Aurora-Brugnetti - Boiler and manometer

- Aurora-Brugnetti - Brewing group

- Aurora-Brugnetti - Electrics

- Aurora-brugnetti - Filterbasket

- Aurora-Brugnetti - Flowmeter

- Aurora-brugnetti - Heating element

- Aurora-Brugnetti - Manometer

- Aurora-brugnetti - Portafilter

- Aurora-brugnetti - pressure switch

- Aurora-Brugnetti - solenoid valve

- Aurora-Brugnetti - Steam/water valve

- Astoria

- Bezzera

- Brasilia

- Carimali

- Casadio

- Conti

- ECM

- Elektra

- ECM Heidelberg

- Faema

- Gaggia

- Grimac

- La Cimbali

- La Pavoni

- La Scala

- La Spaziale

- Nuova Simonelli

- Rocket

- Rancilio

- San Marco

- San Remo

- Vibiemme

- Victoria Arduino

- Wega

- Aurora-brugnetti

- Grinder parts

- grinders

- Tools

- Blog

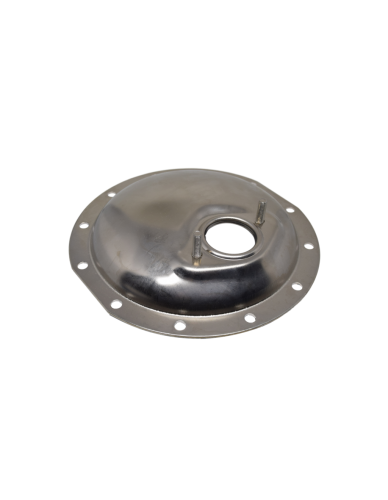

Flange and rings

In the past it was standard that a espresso machine had a flange on 1 or on both sides of the boiler. Nowadays this becomes rarer and rarer. The flange on a boiler can nowadays only be found on the heating element side.

You have 2 types of boiler flanges, the casted ones and the pressed ones. The boiler flanges which are casted, for instance with Gaggia and Vibiemme espresso machines don’t require boiler rings. With the pressed sheet metal ones, for instance on the Faema E61 espresso machine, a aluminium boiler ring is required to spread out the force of the bolts and not deform the soft copper.

The advantage of having a boiler flange on one side is that the cleaning and inspection of a boiler was a lot easier then with just a heating element hole.

There are 5 products.